How Do TOF 3D Cameras Improve Industrial Robot Precision and Safety?

How Can TOF 3D Cameras Enable Smarter, Safer Industrial Robots in Factories?

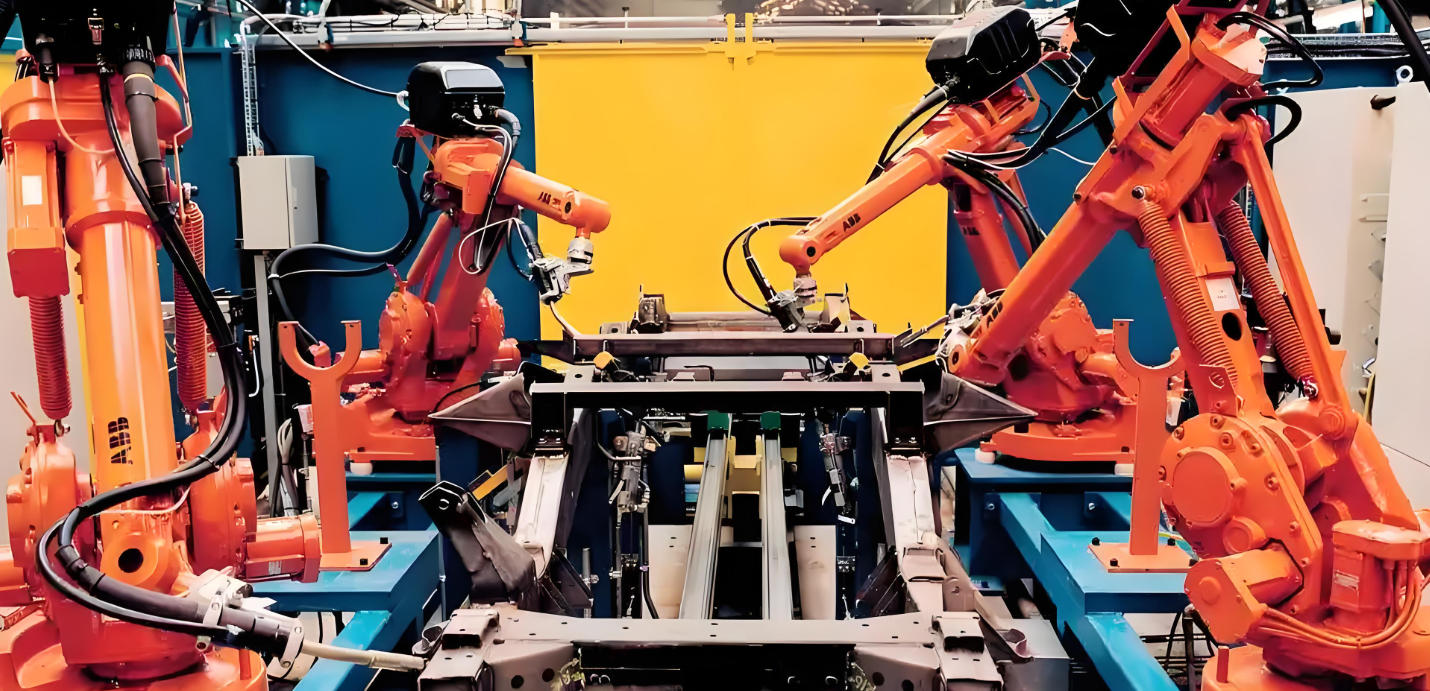

Amid the rapid evolution of Industry 4.0, industrial robots are increasingly required to perform tasks with high precision, efficiency, and safety. Traditional automation systems rely on 2D vision or simple sensors, which struggle to handle complex environments with multiple moving objects or dynamic production lines. TOF (Time-of-Flight) 3D cameras have emerged as a critical technology, enabling real-time depth perception, accurate positioning, and intelligent obstacle avoidance. These cameras provide industrial robots with the spatial awareness necessary for advanced operations, supporting smart factories in achieving automation upgrades and efficiency improvements.

What is a 3D depth camera?

A 3D depth camera captures not only the visual appearance of objects but also their distance from the sensor, generating a three-dimensional representation of the environment. Unlike conventional cameras, which record only color and intensity, depth cameras measure the spatial location of each point, producing accurate 3D maps.

Common technologies in depth cameras include:

-

Time-of-Flight (TOF): Measures the time light takes to return to the sensor after hitting an object.

-

Structured Light: Projects a known pattern onto surfaces and calculates depth from the pattern’s deformation.

-

Stereo Vision: Uses dual cameras to simulate human binocular vision, estimating depth from image disparities.

Depth cameras are widely applied in robotics, AR/VR systems, industrial automation, and smart devices, providing the critical spatial information required for navigation, manipulation, and obstacle avoidance.

How are TOF cameras applied in industrial robots, and why are they advantageous for positioning and safety?

TOF 3D cameras provide industrial robots with real-time spatial perception, allowing them to sense their surroundings accurately. By generating high-resolution depth maps, these cameras help robots identify object locations, measure distances, and plan safe paths. The field of view (FOV) of a TOF camera determines the area a robot can perceive, which is vital for tasks such as assembly, material handling, and automated logistics.

By integrating TOF data with motion planning algorithms, robots can position themselves precisely, adjust for moving objects, and avoid collisions. This spatial awareness transforms traditional robots into intelligent systems capable of autonomous decision-making, safe interaction, and efficient operation.

1. The Need for 3D Perception in Industrial Robots

Industry 4.0 emphasizes flexibility, safety, and efficiency in production. Traditional 2D vision and basic sensors cannot meet the high demands of modern manufacturing, especially for tasks such as precision assembly, dynamic picking, and quality inspection.

2D vision systems often fail in environments with occlusion, variable lighting, or multiple moving objects, leading to misgrasping, collisions, and reduced productivity. In contrast, TOF cameras produce millimeter-level depth measurements and 3D maps in real time, unaffected by lighting conditions or object complexity. This ensures stable, precise perception for industrial robots, enhancing operational accuracy and reliability.

2. TOF Cameras for Precise Positioning

High-precision positioning is critical in automated production lines. TOF cameras provide:

-

Accurate 3D coordinates: Real-time point clouds reveal object positions, dimensions, and orientations.

-

Dynamic tracking: Moving targets are monitored continuously, allowing robots to adjust paths instantly.

-

Improved grasping and efficiency: AI-powered motion planning based on TOF depth data reduces errors, collisions, and downtime.

-

Robust performance: Unlike 2D vision, TOF works reliably under low light, strong light, or occluded conditions.

-

Support for intelligent collaboration: TOF enables multi-robot coordination and integration with AI for autonomous learning and adaptive workflows.

With these capabilities, TOF cameras empower industrial robots to achieve high precision, stable operation, and adaptable performance in complex environments.

3. Obstacle Avoidance and Path Planning

TOF cameras are critical for safe navigation in industrial settings:

-

Real-time 3D mapping: Robots detect equipment, moving objects, and human operators instantly.

-

AGV navigation: Automated Guided Vehicles (AGVs) use TOF data for route planning and obstacle avoidance.

-

Dynamic path optimization: Continuous spatial updates allow robots to select optimal paths for efficiency and safety.

-

Multi-robot safety: TOF depth sensing prevents collisions in environments with multiple robots.

-

Environmental adaptability: Depth perception remains accurate under challenging lighting or cluttered conditions.

These features ensure both operational efficiency and workplace safety, making TOF indispensable for modern industrial automation.

4. Balancing Cost and Performance

TOF cameras provide a strong cost-performance ratio compared to alternatives like LiDAR or stereo vision:

-

Cost-effective: Smaller, lighter, and less expensive than LiDAR while maintaining sufficient depth accuracy.

-

Reliable under varied lighting: Single-camera design performs stably under low-light or high-glare conditions.

-

Optimized deployment: Strategic placement maximizes coverage, reduces blind spots, and improves grasp success.

-

Energy-efficient and maintainable: Low power consumption, modular design, and minimal downtime support long-term use.

-

Scalable and upgradeable: Integration with AI, edge computing, and multi-sensor fusion supports future factory upgrades.

TOF technology achieves precision, flexibility, and operational efficiency while remaining cost-effective for industrial deployment.

5. Future Trends: AI + TOF for Smart Factories

AI integration with TOF depth sensing is driving industrial robots toward fully intelligent factories:

-

Autonomous learning: AI uses TOF depth data for path optimization, error reduction, and adaptive motion planning.

-

Collaborative robots (Cobots): TOF allows multiple robots to share environmental data, enabling safe collaboration and human-robot interaction.

-

Predictive production: TOF depth maps combined with AI predict anomalies and optimize workflow.

-

Digital twin integration: Real-time 3D data supports visualization, monitoring, and remote control of production lines.

-

Flexible, intelligent applications: Unmanned warehouses, automated assembly, precision machining, and predictive maintenance benefit from AI + TOF synergy.

With AI-powered TOF perception, industrial robots evolve from simple automation to intelligent, collaborative, and predictive production systems, enabling smart factories to achieve unprecedented efficiency, safety, and adaptability.

Conclusion

TOF 3D cameras are transforming industrial robotics, providing precise positioning, real-time obstacle avoidance, and intelligent path planning. Integrated with AI, TOF enables high-efficiency, safe, and scalable operations, forming the foundation for the next generation of smart factories and intelligent manufacturing.

Okulo™ P1 Precision RGB-Depth Sensing Camera: High-Quality Imaging, Advanced Time-Of-Flight Technology,100FPS, And Robust Hardware Integration

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.