How Do TOF 3D Cameras Enhance Accuracy and Precision in Industrial QC?

How Does TOF 3D Inspection Enhance Accuracy vs Precision in Industrial Quality Control?

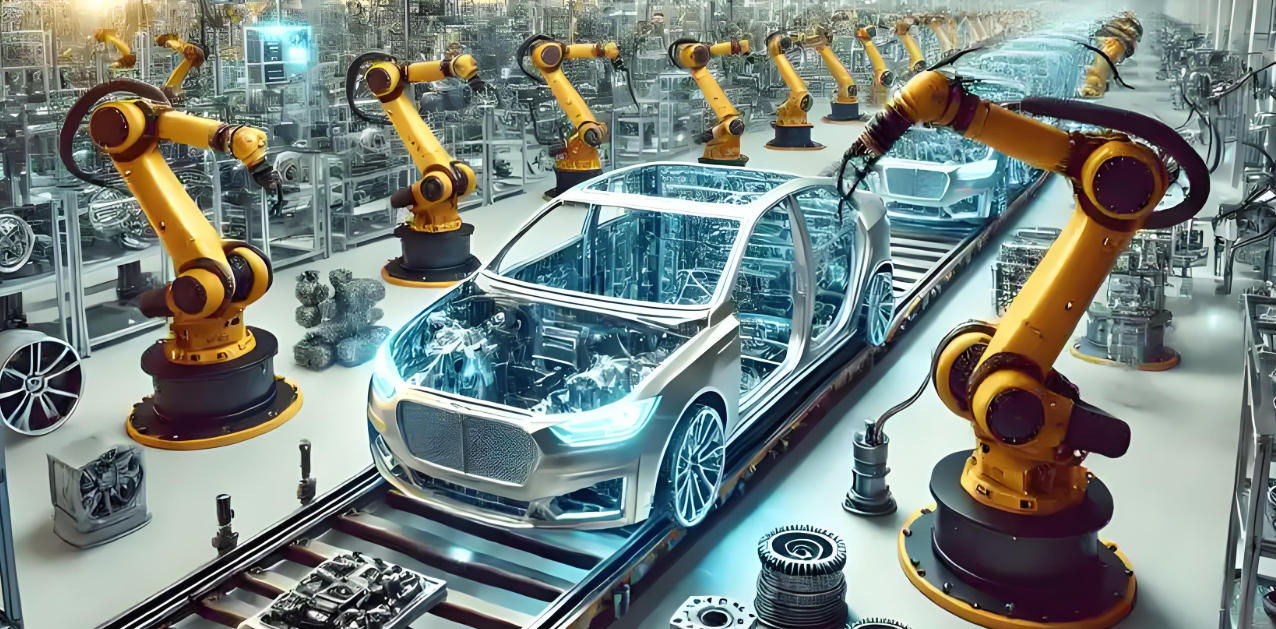

In the era of smart manufacturing and Industry 4.0, industrial production lines demand both efficiency and high-quality standards. Traditional inspection methods, such as manual checks or 2D imaging, often fail to guarantee precision and reliability, especially in high-speed or complex production scenarios. The integration of TOF (Time-of-Flight) 3D depth cameras into industrial inspection has transformed quality control, enabling accurate, fast, and automated measurement. This article explores the advantages of TOF inspection, its industrial applications, and how it effectively balances accuracy vs precision on production lines.

What Is a 3D Depth Camera?

A 3D depth camera captures not only visual images but also spatial distance information, producing a detailed 3D map of objects or scenes. Unlike standard cameras, it measures the distance from each point to the sensor, generating a point cloud that allows precise object recognition and dimensional analysis.

Working Principles of 3D Depth Cameras

-

Time-of-Flight (TOF): Emits infrared or laser pulses and measures the time taken for the light to return, calculating the distance for each pixel.

-

Structured Light: Projects a specific pattern onto the object and measures deformation to reconstruct 3D geometry.

-

Stereo Vision: Uses dual cameras to simulate human binocular vision, calculating depth from disparities between images.

With TOF 3D depth cameras, devices can perceive 3D shapes and positions accurately, making them essential for industrial inspection, smart devices, and automated quality control.

1. Challenges in Industrial Quality Control

Even with advanced manufacturing, traditional inspection methods face limitations:

-

Human Error: Manual checks rely on experience and subjective judgment. Fatigue or inconsistency can reduce both accuracy and precision.

-

Low Efficiency: High-throughput lines, like electronics or automotive assembly, require rapid inspections that manual processes cannot meet.

-

2D Camera Limitations: Standard cameras fail to capture 3D surface features, missing minor defects, dimensional deviations, or geometric errors.

These issues highlight the need for 3D inspection technologies that provide reliable accuracy and precision, ensuring consistency across production batches.

2. How TOF Enhances Industrial 3D Inspection

TOF inspection measures the flight time of light pulses to generate high-precision depth data. Key advantages include:

-

Surface Defect Detection: Identifies scratches, dents, or burrs quickly, improving accuracy vs precision.

-

Dimensional Measurement: Measures length, width, height, angles, and geometric alignment in real-time, supporting precision-critical applications.

-

High-Speed Operation: Capable of inspecting moving parts or high-throughput assembly lines without slowing production.

-

Environmental Robustness: Performs reliably in bright, dim, or reflective industrial environments.

By enabling real-time 3D inspection, TOF cameras shift quality control from post-production defect discovery to proactive monitoring.

3. Industrial Application Cases

Electronics Manufacturing

In PCB production, small misalignments in solder joints can lead to defective boards. Traditional 2D inspection may miss micron-level defects. TOF cameras provide high-resolution 3D point clouds, ensuring both accuracy and precision, and allowing millisecond-level defect detection. This improves yield, reduces rework, and enhances overall reliability.

Automotive Industry

Assembly precision is crucial for automotive safety. Misaligned bolt holes or uneven welds can compromise vehicle integrity. TOF inspection ensures real-time measurement of critical components, detecting deviations as small as 0.1 mm. By monitoring accuracy vs precision, TOF helps maintain consistent assembly quality across production batches.

4. Comparison with Other 3D Inspection Technologies

| Technology | Accuracy | Precision | Suitability for High-Speed Lines |

|---|---|---|---|

| Laser Scanning | High | High | Low (slow scanning) |

| Structured Light | Medium | Medium | Moderate (sensitive to lighting) |

| TOF 3D Camera | High | High | Excellent (real-time, robust) |

TOF stands out by combining speed, environmental robustness, and reliable depth measurement, effectively balancing accuracy vs precision in industrial inspections.

5. Understanding Accuracy vs Precision

-

Accuracy: How close a measurement is to the true value.

-

Precision: How consistent repeated measurements are.

Examples:

-

High precision, low accuracy: Repeated measurements are close to each other but far from the true value.

-

High accuracy, low precision: Measurements are scattered but average near the true value.

-

TOF inspection achieves both: measurements are close to the true value and consistent across batches, ensuring reliable quality control.

6. Future Trends in TOF 3D Inspection

-

Multi-Sensor Fusion: Combining TOF with RGB cameras, infrared sensors, and laser modules for comprehensive defect detection.

-

AI-Powered Quality Control: Machine learning predicts potential defects and adjusts inspection parameters automatically.

-

Adaptive Inspection: Dynamic adjustment of inspection speed and precision based on product type or batch requirements.

-

Predictive and Intelligent Quality Management: From defect detection to defect prevention, TOF becomes central to Industry 4.0 smart factories.

The combination of TOF + AI + multi-sensor platforms enables fully automated, intelligent, and adaptive quality control systems for modern industrial production.

Conclusion

TOF 3D inspection is transforming industrial quality control by providing high-speed, accurate, and precise measurement. It addresses limitations of manual and 2D inspection methods, ensures consistent product quality, and integrates with AI for predictive and adaptive inspection. As a core component of Industry 4.0, TOF 3D depth cameras drive efficiency, reliability, and intelligence across modern production lines, achieving true balance between accuracy vs precision in industrial quality control.

IHawk 100E 3D Structured Light Camera With VGA Resolution And 0.3-8 Meters Range

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.