Revolutionizing Infrastructure Inspection with TOF Technology

With rapid urbanization and technological advancements, the demand for efficient and precise infrastructure inspection has become increasingly critical. Bridges, tunnels, roads, and buildings require continuous monitoring to ensure public safety, longevity, and structural stability. However, traditional manual inspection methods are often time-consuming, labor-intensive, and prone to human error. To address these challenges, Time of Flight (TOF) technology has emerged as a cutting-edge solution, offering high-precision 3D depth perception to enhance inspection efficiency and minimize risks.

What is a TOF Sensor?

A TOF (Time of Flight) sensor calculates the distance between the sensor and an object by measuring the time it takes for a light pulse to travel to the target, reflect back, and return. By capturing this time delay, TOF sensors generate millimeter-level accurate 3D spatial data, making them ideal for structural assessment, automated inspection, and environmental monitoring.

Unlike traditional inspection methods that rely on visual or contact-based measurements, TOF technology provides high-precision 3D point cloud data, unaffected by ambient lighting conditions. This capability makes TOF sensors invaluable in robotics navigation, autonomous vehicles, industrial automation, and infrastructure health monitoring.

Key Applications of TOF Technology in Infrastructure Inspection

1. Bridge and Tunnel Health Monitoring

Bridges and tunnels are critical to transportation networks, requiring regular assessments to detect structural weaknesses. TOF technology enables:

- High-precision surface scanning to detect cracks, deformation, and settlement

- Real-time 3D mapping, providing detailed structural health data

- Non-contact, automated inspections, reducing the need for manual labor in hazardous environments

For tunnel inspections, where low-light conditions and narrow spaces pose challenges, infrared-based TOF sensors offer uninterrupted monitoring, ensuring continuous and accurate data collection.

2. Road and Traffic Infrastructure Inspection

Road deterioration, including cracks, potholes, and subsidence, directly impacts traffic safety and operational efficiency. TOF sensors enable:

- Rapid, high-resolution surface scanning for road damage detection

- Real-time 3D mapping, allowing for efficient road maintenance planning

- Automated inspections of traffic signals, signage, and barriers, reducing manual labor costs

By integrating TOF sensors with autonomous inspection vehicles, cities can optimize road maintenance schedules, improving safety and cost efficiency.

3. High-Rise Building and Structural Evaluation

High-rise buildings and complex architectural structures require continuous monitoring to prevent long-term structural failures. TOF sensors provide:

- Non-contact, real-time structural analysis, detecting tilting, settlement, and facade cracks

- Comprehensive 3D scans, improving structural health assessments

- Drone-based inspections, reducing manual labor risks in high-altitude monitoring

TOF technology ensures that even hidden or hard-to-reach areas of a building are accurately monitored, enhancing long-term safety and maintenance strategies.

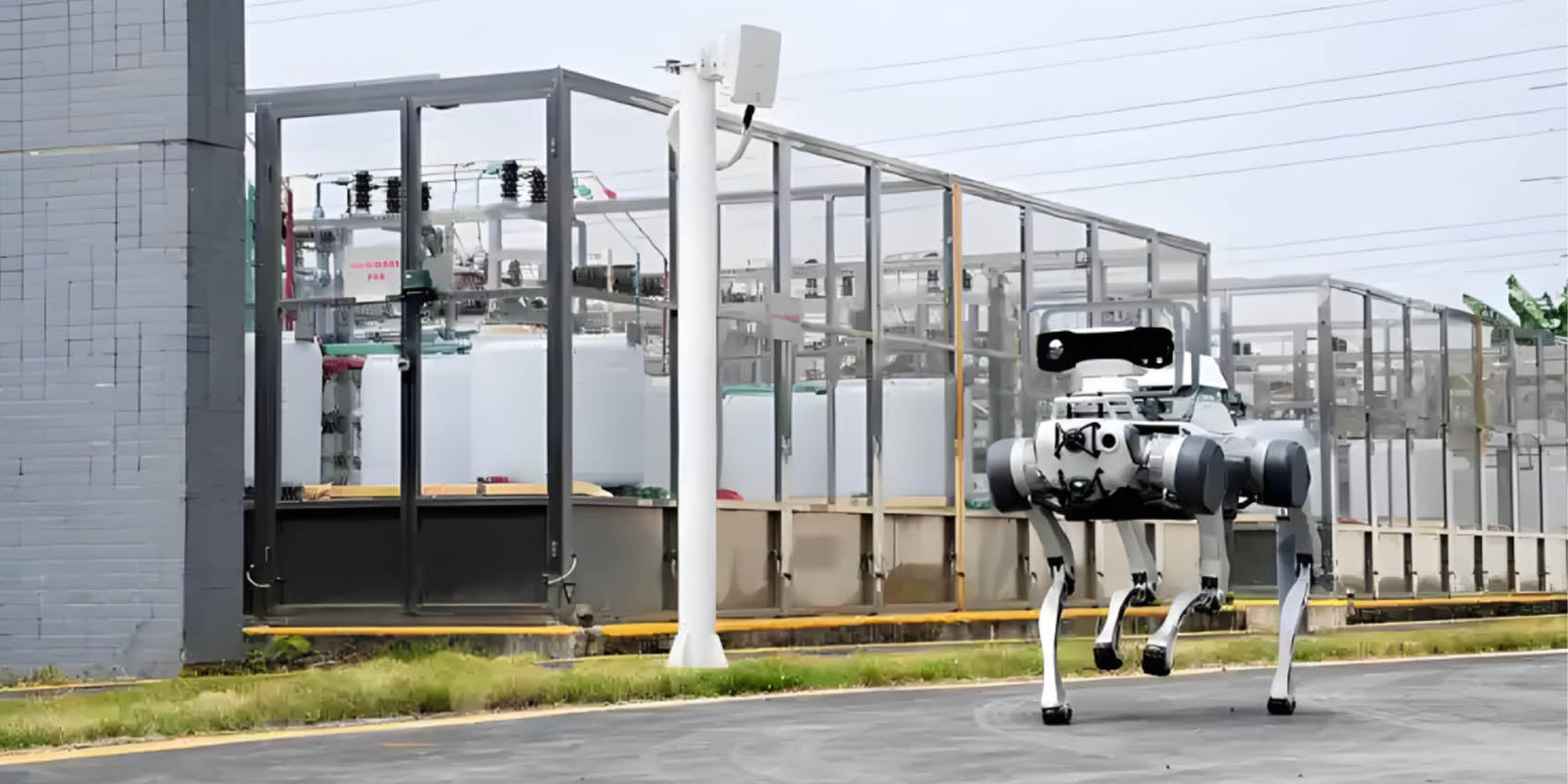

4. Power Facility Monitoring and Safety Assessments

Power infrastructure, including substations, transformers, and power lines, demands highly accurate, non-contact monitoring to ensure operational stability. TOF sensors can:

- Detect surface wear, corrosion, or potential failures in electrical components

- Perform real-time structural scans, reducing the need for manual, high-altitude inspections

- Improve predictive maintenance strategies, ensuring continuous power grid reliability

By implementing automated TOF-based inspections, utility companies can minimize downtime, prevent equipment failures, and enhance worker safety.

5. Environmental Monitoring and Disaster Prevention

Natural disasters such as earthquakes, floods, and landslides pose significant risks to infrastructure stability. TOF technology can:

- Monitor real-time structural changes following severe weather events

- Assess damage to bridges, tunnels, and buildings, enabling faster emergency responses

- Support early disaster warning systems, reducing economic and human losses

By integrating TOF sensors with AI-powered analytics, cities can improve disaster preparedness, enhancing infrastructure resilience and safety measures.

Advantages of TOF Technology in Infrastructure Inspection

1. High Precision and Real-Time Data Processing

With millimeter-level accuracy, TOF technology provides detailed surface analysis, allowing for:

- Early detection of cracks, deformations, and structural weaknesses

- Accurate depth mapping, crucial for infrastructure risk assessments

- Reduced dependency on manual inspections, minimizing human error

2. Works in All Lighting and Weather Conditions

Unlike traditional vision-based inspection tools, TOF sensors use infrared light pulses, allowing them to function:

- In bright daylight, darkness, or low-light conditions

- In challenging weather, such as fog, rain, or dust

- Underground, in tunnels, and other confined spaces

This all-weather functionality makes TOF technology an ideal solution for continuous infrastructure monitoring.

3. Adaptability to Complex Environments

Whether inspecting bridges, tunnels, roads, or underground systems, TOF sensors offer:

- Non-contact, high-resolution scanning

- Data collection in hard-to-reach or hazardous locations

- Integration with AI and autonomous inspection drones

This adaptability ensures comprehensive, automated monitoring, improving efficiency and cost-effectiveness.

4. Cost-Efficient and Time-Saving

Automating infrastructure inspections with TOF technology reduces:

- Labor costs by minimizing manual inspections

- Maintenance expenses through predictive analysis

- Inspection time, allowing for faster decision-making and repair planning

By reducing operational costs while improving efficiency, TOF technology provides long-term economic benefits.

The Future of TOF Technology in Smart Infrastructure Management

With advancements in AI, 5G, and IoT, TOF sensors will continue to evolve, integrating:

- AI-driven data analysis for automated risk detection

- Cloud-based TOF monitoring systems for remote infrastructure management

- Real-time predictive maintenance models, reducing unexpected failures

As urban infrastructure expands, TOF-driven automated inspections will play a pivotal role in smart city development, ensuring safer, more resilient, and sustainable infrastructure systems.

Conclusion

TOF technology is transforming infrastructure inspection, offering high-precision, real-time monitoring for bridges, roads, buildings, and power facilities. With its unmatched accuracy, adaptability, and automation capabilities, TOF technology enhances safety, efficiency, and sustainability in urban infrastructure management.

As the world moves toward smarter cities, TOF-based automated inspections will become a cornerstone of modern infrastructure monitoring, driving cities toward a safer, more intelligent future.

IHawk Structured Light Camera 072 1.5M

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.

-

Posted in

072