How TOF Sensors Boost Industrial Robot Positioning & Smart Factory

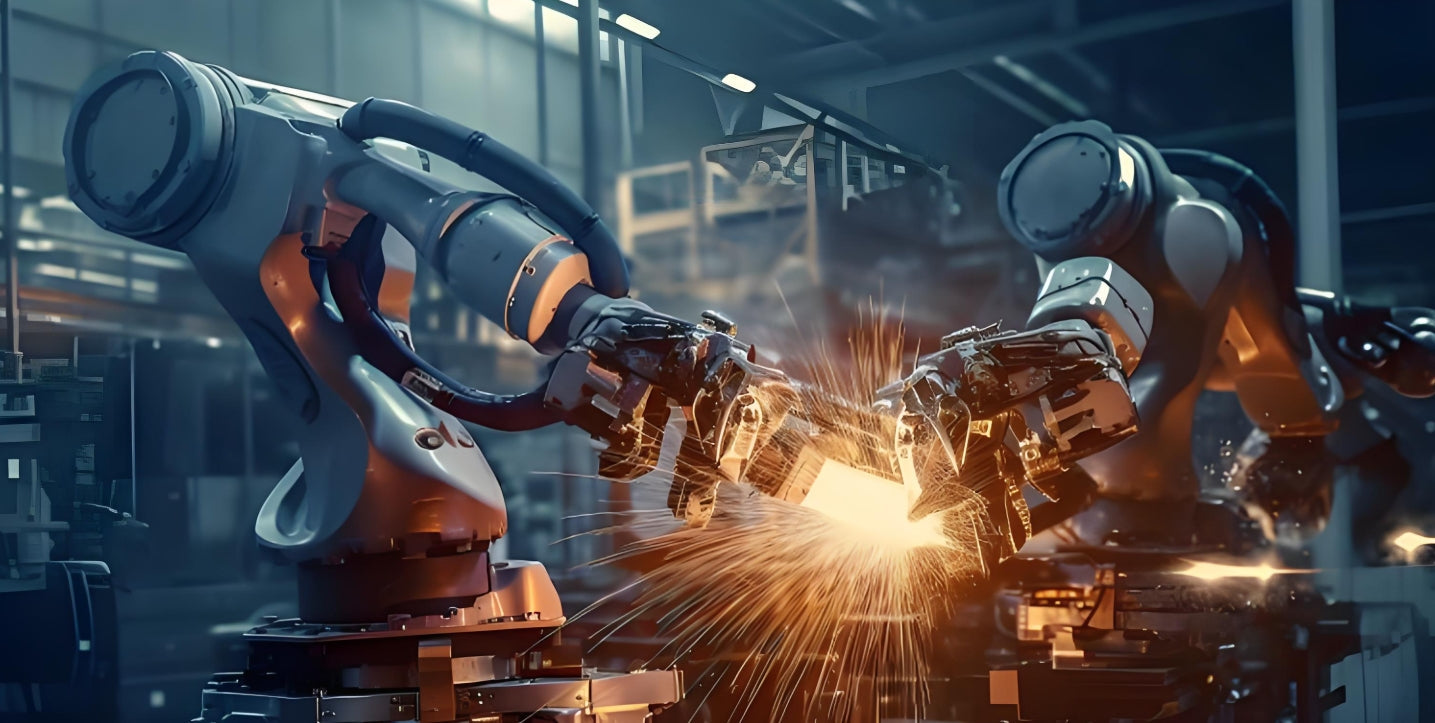

With the rapid development of Industry 4.0, smart manufacturing is revolutionizing traditional industrial processes. Automation, precision, and efficiency have become the cornerstone demands of modern manufacturing. Among various technologies, time-of-flight (TOF) sensor-based 3D sensing stands out as a powerful solution for industrial robot positioning, distance measurement, obstacle avoidance, and more — thanks to its high accuracy and fast response.

Advantages of TOF Sensors in Industrial Robot Positioning

High-Precision 3D Ranging

TOF sensors calculate the flight time of emitted light pulses to capture precise 3D depth information of objects with millimeter-level accuracy. This enables industrial robots to gain exact spatial positioning data, significantly improving the precision of operations such as assembly, handling, and inspection.

Real-Time Rapid Response

The high-speed responsiveness of TOF technology allows robots to detect spatial changes instantly, adapting quickly to dynamic industrial environments. This agility enhances production line flexibility and operational efficiency.

Robust Anti-Interference Performance

Unlike traditional vision systems, TOF sensors maintain stable performance under challenging conditions including variable lighting, dust, and smoke. This resilience ensures continuous, reliable positioning data critical for complex industrial settings.

Compact and Easy to Integrate

TOF sensors are lightweight, energy-efficient, and compact. Their seamless integration into industrial robots and automation equipment simplifies hardware layout and reduces system complexity.

Rich 3D Spatial Data

Beyond 2D imaging, TOF sensors generate dense 3D point clouds, offering a comprehensive environmental view that supports sophisticated path planning and obstacle avoidance.

Multi-Sensor Fusion Support

TOF sensors can be combined with RGB cameras, LiDAR, and other sensor technologies to enhance accuracy and robustness in robot positioning, enabling smarter environmental perception and autonomous decision-making.

Meeting Automation Needs in Smart Manufacturing

In the Industry 4.0 era, manufacturing equipment must not only automate operations but also intelligently perceive their surroundings and respond rapidly. Accurate real-time 3D spatial information is crucial for recognizing the position, posture, and status of workpieces, enabling flexible, efficient production.

Traditional 2D vision systems are limited by sensitivity to lighting and occlusion and cannot deliver precise depth data required for complex tasks. While LiDAR offers some 3D capabilities, it is often bulky, costly, and less stable in dusty or smoky environments.

TOF-based 3D camera solutions overcome these limitations with their compact size, low power consumption, fast response, and strong interference resistance. This makes TOF technology ideal for upgrading smart manufacturing automation.

By integrating high-performance TOF sensors, equipment can perform real-time positioning and ranging of complex parts, automate assembly, inspection, and quality control, thereby improving automation levels and product consistency. The use of 3D vision inspection minimizes human errors and equipment failures, enhancing overall production efficiency and competitiveness.

TOF Sensors for Industrial Robot Positioning, Ranging, and Obstacle Avoidance

Equipped with advanced TOF 3D cameras, industrial robots achieve millimeter-level accuracy in measuring distances and modeling 3D environments by calculating light pulse flight times. This technology captures spatial data for both static and dynamic objects, improving autonomous positioning and path planning.

Robots use precise TOF distance data to perceive their surroundings and navigate safely, avoiding both fixed and moving obstacles. In multi-robot setups, TOF sensors update environmental models in real time, optimize trajectories, reduce collisions, and boost system coordination.

TOF sensors perform reliably even in harsh industrial conditions such as smoke, dust, and complex lighting. Coupled with AI and machine learning, robots utilize dense 3D point clouds for accurate object recognition and dynamic decision-making, elevating automation levels.

In electronics manufacturing, 3C assembly, and automotive sectors, TOF cameras assist with 3D vision inspection and quality control, identifying tiny component positions and morphological changes to reduce defects and costs. Integration with RGBD cameras further enhances robotic perception by combining depth with color information.

Industrial drones also benefit from TOF 3D sensors for logistics, warehousing, and inspection applications. TOF-enabled drones perform obstacle avoidance and gesture-controlled operation for safer, more flexible missions in smart manufacturing environments.

Key Functions of TOF Sensors in Robotics

-

Robot Positioning: TOF sensors generate precise 3D depth maps by measuring light flight times, enabling real-time spatial positioning critical for robot accuracy and efficiency.

-

Robot Ranging: Millimeter-level distance measurement and high-resolution depth data allow robots to precisely gauge distances for path planning and task execution.

-

Robot Obstacle Avoidance: Real-time 3D point cloud data enables robots to identify and avoid obstacles, both stationary and moving, enhancing safety and operational continuity.

Comparative Advantages Over Traditional Vision and LiDAR

Traditional RGBD cameras depend heavily on lighting conditions and produce noisy data in challenging environments, limiting accuracy. LiDAR systems, while capable of 3D ranging, are bulky, expensive, and less stable in dust or smoke-filled industrial settings.

TOF sensors excel by offering compact design, low power consumption, fast response, and strong environmental resistance. They provide continuous, high-density 3D point cloud data in real time, ideal for advanced AI-driven vision tasks such as defect detection and dynamic obstacle avoidance.

Overall, TOF technology offers superior performance, cost-effectiveness, and adaptability, establishing itself as a core sensing solution for Industry 4.0 smart manufacturing.

Case Study: 3C Electronics Assembly with TOF Visual Positioning

In the electronics assembly sector, where components are tiny and varied, precise positioning and fast adaptation are vital. Traditional 2D vision systems often fall short.

A TOF 3D camera visual positioning system with integrated TOF sensors captures 3D spatial data in real time, achieving millimeter-level precision. This system combines advanced sensing with intelligent algorithms to identify small components, detect assembly deviations, and ensure consistent product quality.

Seamless integration with automated control platforms enables flexible, coordinated operation of production equipment, supporting small-batch and multi-variety manufacturing efficiently. The result is improved productivity, reduced maintenance, and greater operational stability, fueling smart manufacturing upgrades.

The Future of TOF in Industry 4.0

Advances in semiconductor chips and sensor algorithms will drive next-generation TOF sensors toward lower cost, higher integration, and miniaturization. Future sensors will offer enhanced accuracy and broader detection ranges, enabling real-time 3D sensing in increasingly complex industrial environments.

Industry 4.0’s smart factory vision will promote deep integration of TOF sensors for comprehensive environmental monitoring and intelligent equipment management. TOF-based sensing will optimize positioning, obstacle avoidance, and drone operations—including gesture-controlled drones—for enhanced flexibility.

Coupled with AI and big data analytics, TOF sensors will evolve into intelligent neural hubs for predictive maintenance, quality assurance, and safety, further advancing manufacturing automation, efficiency, and responsiveness in Industry 4.0.

SLAMTEC RPLIDAR LPX-E3 25m 360° 2D LiDAR for AGV Obstacle Avoidance

After-sales Support:

Our professional technical team specializing in 3D camera ranging is ready to assist you at any time. Whether you encounter any issues with your TOF camera after purchase or need clarification on TOF technology, feel free to contact us anytime. We are committed to providing high-quality technical after-sales service and user experience, ensuring your peace of mind in both shopping and using our products.