Enhancing Safety Monitoring with TOF Technology to Mitigate Risks

In modern industrial environments, safety remains the highest priority, especially in high-risk industries such as chemical plants, mining, smelting, and manufacturing. Traditional safety monitoring systems, which rely on cameras and infrared sensors, often face limitations in complex conditions like extreme lighting, smoke, and environmental interference. TOF (Time of Flight) technology, with its precise 3D depth perception, is rapidly becoming an essential tool for improving industrial safety by offering stable performance in challenging environments and delivering enhanced protection for workers and production processes.

How TOF Technology Enhances Industrial Safety

TOF technology works by emitting light pulses and measuring the time taken for them to return, providing precise 3D depth information of objects. Unlike traditional 2D sensors, TOF sensors operate accurately in complex environments where other systems may struggle. They offer unparalleled reliability in industries that involve extreme conditions such as high temperatures, low visibility, and smoke, ensuring that critical safety data is captured without interference.

No Lighting Dependency for Enhanced Accuracy

A key advantage of TOF technology is that it does not rely on ambient lighting, unlike traditional cameras or infrared sensors that may struggle in low-light or overly bright conditions. TOF sensors emit their own light pulses and accurately measure the time it takes for the pulse to return. This makes them perfect for high-risk environments like chemical plants or smelting factories, where lighting conditions can vary drastically and disrupt conventional monitoring devices.

High-Precision Measurement in Hazardous Environments

TOF technology’s ability to offer high-precision distance measurements is a game-changer in industries that require exact spatial data for safety purposes. In environments with extreme temperatures, pressure, or motion, TOF sensors provide real-time, millimeter-level accuracy. This feature is critical in situations where small changes could result in catastrophic accidents, such as in automated assembly lines or heavy machinery operation, where precise personnel tracking is essential for preventing injuries.

Virtual Safety Fences with TOF Technology

In high-risk production settings, virtual safety fences are vital for ensuring workers remain in safe zones. TOF sensors enable the creation of these virtual fences by monitoring the movement of people and equipment in real time. In environments like smelting plants or chemical factories, where physical barriers might not be feasible due to environmental hazards, TOF technology can create virtual boundaries to keep workers out of dangerous zones. The system automatically triggers safety measures, such as alerts or shutdown procedures, if someone enters a restricted area.

Integration with Automated Safety Systems

TOF technology does not only function as an independent safety monitoring solution—it can also be integrated with other systems for a comprehensive safety network. For example, by connecting TOF sensors with gas leak detectors, temperature sensors, and other safety devices, industries can achieve multi-layered protection. In a mining or manufacturing environment, this integrated system can detect and respond to a wide range of hazards such as hazardous gas leaks or abnormal equipment behavior, activating preventive measures before accidents occur.

Real-Time Environmental Monitoring

TOF technology excels in environments with frequent changes or unstable conditions. For instance, in industries like pharmaceuticals and food processing, maintaining a cleanroom environment is crucial for product quality. TOF sensors can accurately monitor even the smallest environmental changes in these controlled spaces, such as unauthorized movements or shifts in temperature, to prevent contamination. The same principle applies to areas prone to extreme heat, pressure, or the presence of toxic gases, where TOF technology helps to monitor air quality and detect potential hazards.

Use Cases in High-Risk Industries

-

Chemical Industry: In chemical plants, where toxic gas leaks and hazardous materials are common risks, TOF sensors provide real-time personnel tracking and gas leak detection, helping to prevent exposure to dangerous environments.

-

Smelting Industry: With the intense heat and hazardous working conditions in smelting operations, TOF technology ensures that workers remain at safe distances from dangerous equipment by accurately tracking their location and triggering timely safety alerts.

-

Mining Industry: The complexity of mining environments requires constant monitoring. TOF technology allows real-time tracking of workers' 3D positions, helping prevent them from entering dangerous zones and enabling quick responses to environmental changes.

Conclusion

TOF technology is revolutionizing industrial safety by providing real-time, high-precision monitoring in complex and hazardous environments. By offering accurate 3D depth measurements, operating independently of lighting conditions, and integrating seamlessly with other safety systems, TOF sensors improve overall safety, helping industries prevent accidents and ensure a safer working environment. As industrial automation continues to advance, the role of TOF technology in safety management will expand, providing essential protection in high-risk production processes across the globe.

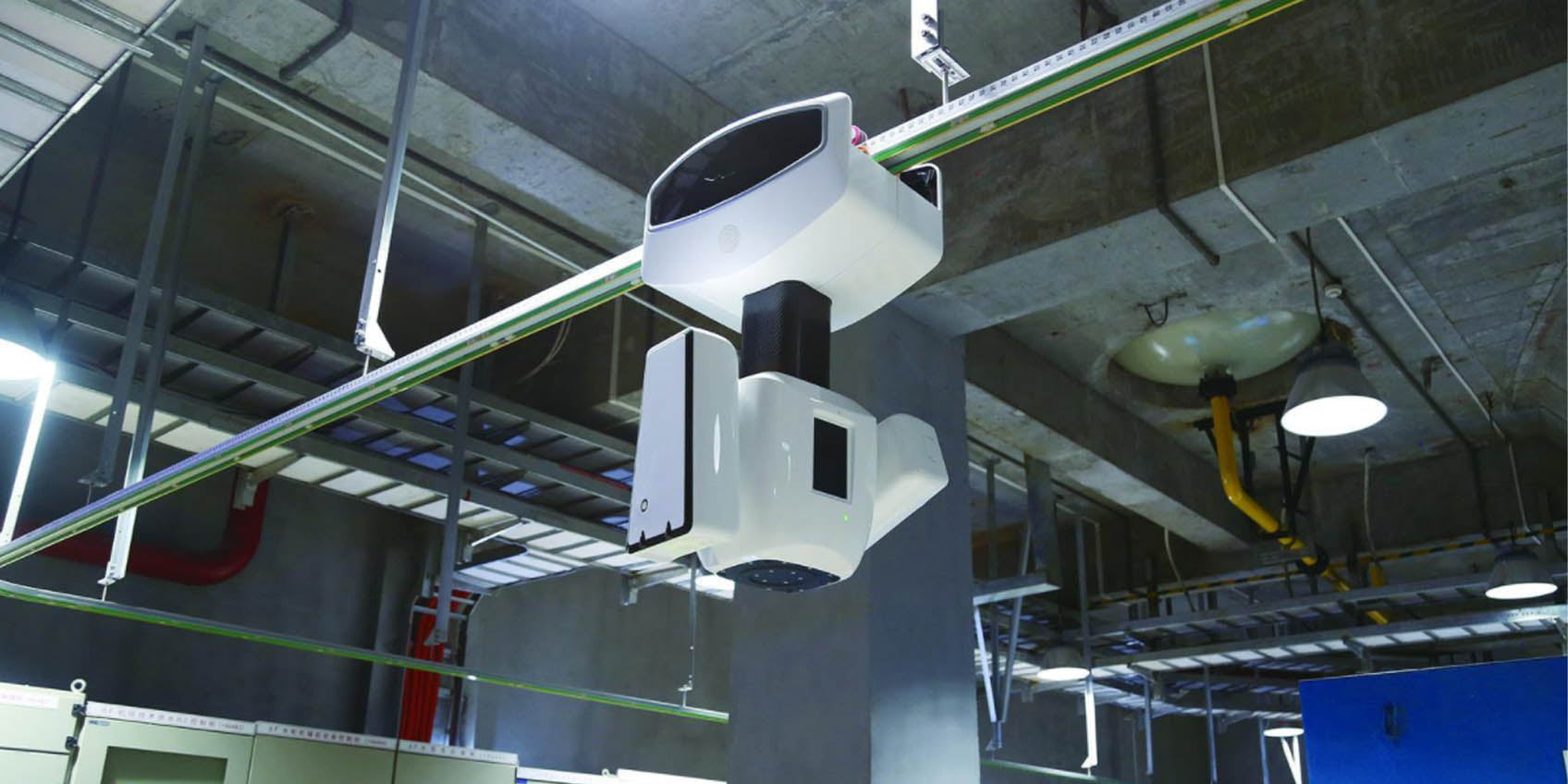

XT-S240 Mini 106°×80°, Outdoor 10m, Indoor 12m Solid-State Flash Lidar

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.

-

Posted in

XT-S240