Enhancing Production Line Quality with TOF Technology & AI Integration

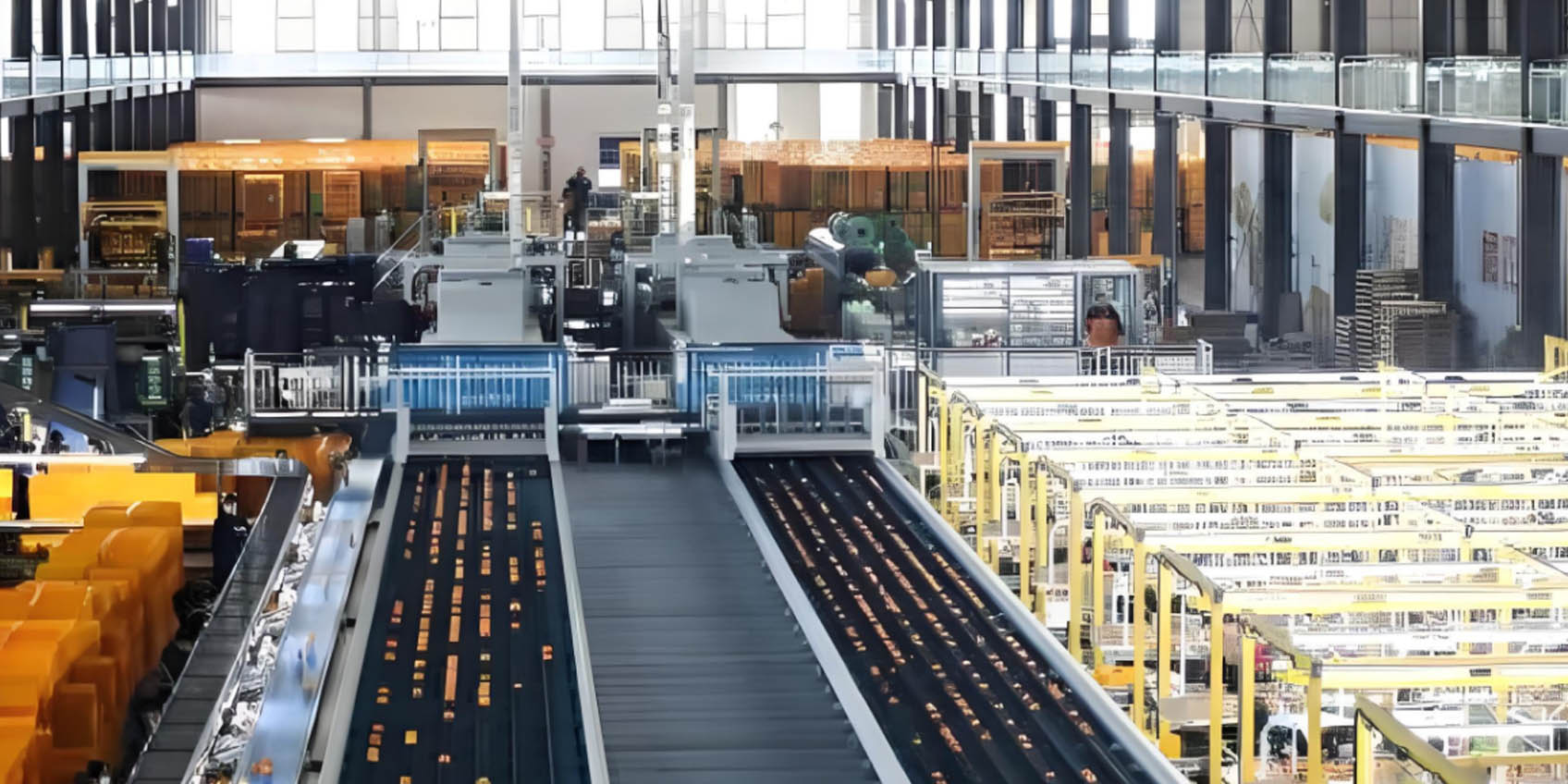

In the modern manufacturing industry, there is a growing focus on improving production quality and efficiency. TOF (Time of Flight) technology has emerged as a crucial tool for enhancing the precision of quality inspections on production lines. With its ability to provide high-precision distance measurements and real-time data collection, TOF technology allows for detailed inspections of products, ensuring they meet stringent quality standards.

When integrated with AI visual inspection algorithms, TOF technology offers even greater efficiency and accuracy in production line quality inspections. This combination is revolutionizing quality control, helping manufacturers improve production efficiency and product consistency.

What is TOF Technology?

TOF technology (Time of Flight) works by emitting light pulses and measuring the time it takes for them to return after hitting an object. This enables precise measurements of the distance, size, and position of objects, making TOF ideal for high-precision applications. In manufacturing, TOF sensors are used to measure product dimensions, shapes, and positions in three-dimensional space, providing detailed data for more accurate quality control.

One of the key advantages of TOF technology is its ability to operate in various lighting and environmental conditions. Unlike traditional optical sensors that rely on external light sources, TOF sensors deliver consistent performance in both bright and low-light environments, ensuring stable data output in dynamic production conditions.

Advantages of TOF Technology in Quality Inspection

High Precision for Product Quality Assurance

TOF technology offers millimeter-level precision, which is essential for ensuring the quality of products in fields like electronics, automotive, aerospace, and pharmaceuticals. For instance, in electronics manufacturing, TOF sensors can measure the exact dimensions of circuit boards and the placement of components, ensuring the final product meets rigorous standards.

Real-Time Monitoring and Automation

TOF sensors provide real-time data collection during the production process, enabling quick identification of deviations and defects. When combined with AI algorithms, the data is processed and analyzed instantly, allowing automated defect detection and immediate feedback. This reduces human intervention and enhances overall production efficiency.

Adaptability to Complex Conditions

Manufacturing environments often involve fluctuating lighting, temperature, and humidity, which can affect the stability of traditional optical sensors. TOF technology, however, remains unaffected by these external factors, providing reliable and accurate data under a wide range of environmental conditions.

Improved Efficiency and Faster Production

The integration of TOF technology with AI algorithms helps speed up production processes. By automating the detection of dimensional and surface defects (such as cracks, dents, or scratches), TOF-equipped systems can quickly identify issues without the need for manual inspection, significantly reducing inspection time and increasing overall production speed.

The Role of AI Visual Inspection Algorithms

When TOF technology is combined with AI visual inspection algorithms, it takes production line quality control to the next level. AI algorithms can analyze large amounts of data to detect defects such as dimensional deviations, shape irregularities, and surface flaws. This real-time analysis allows immediate corrections to be made, reducing downtime and improving product consistency.

AI algorithms can also compare real-time data with historical data, enabling predictive maintenance and early warnings for potential quality issues. This proactive approach reduces defects before they happen, improving the overall quality of products.

Applications of TOF Technology in Quality Inspection

Electronics Manufacturing

In electronics production, TOF sensors can perform high-precision measurements of circuit boards and components. AI algorithms help detect issues such as improper solder joints or component misalignment, ensuring high-quality, defect-free electronics.

Automotive Industry

TOF technology is widely used in the automotive sector for inspecting parts like engine components, body panels, and safety-critical parts. By providing precise 3D measurements, TOF sensors can detect minor defects, ensuring that all automotive parts meet safety and quality standards.

Food Packaging

In the food industry, TOF sensors can inspect food packaging for defects such as loose seals or damage, helping maintain the integrity of the packaging and ensuring that products are safe for consumption.

Pharmaceutical Production

TOF sensors play a crucial role in ensuring the quality of pharmaceutical packaging. They can verify that bottles are properly sealed and labeled, meeting size and quality standards. AI visual algorithms help detect minor packaging defects, ensuring high standards in pharmaceutical manufacturing.

Conclusion

The integration of TOF technology and AI visual inspection algorithms has transformed production line quality inspection. These technologies improve precision, automation, and adaptability, significantly enhancing overall manufacturing efficiency. With ongoing advancements, TOF technology will continue to play an increasingly vital role in smart manufacturing and quality control, helping industries achieve higher production standards and greater efficiency.

By adopting TOF and AI technology, manufacturers are not only improving product quality but also streamlining their production processes, paving the way for a smarter, more efficient future in manufacturing.

Synexens Industrial Outdoor 10m TOF Sensor Depth 3D Camera Rangefinder-CS40 Pro

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.

-

Posted in

CS40 Pro