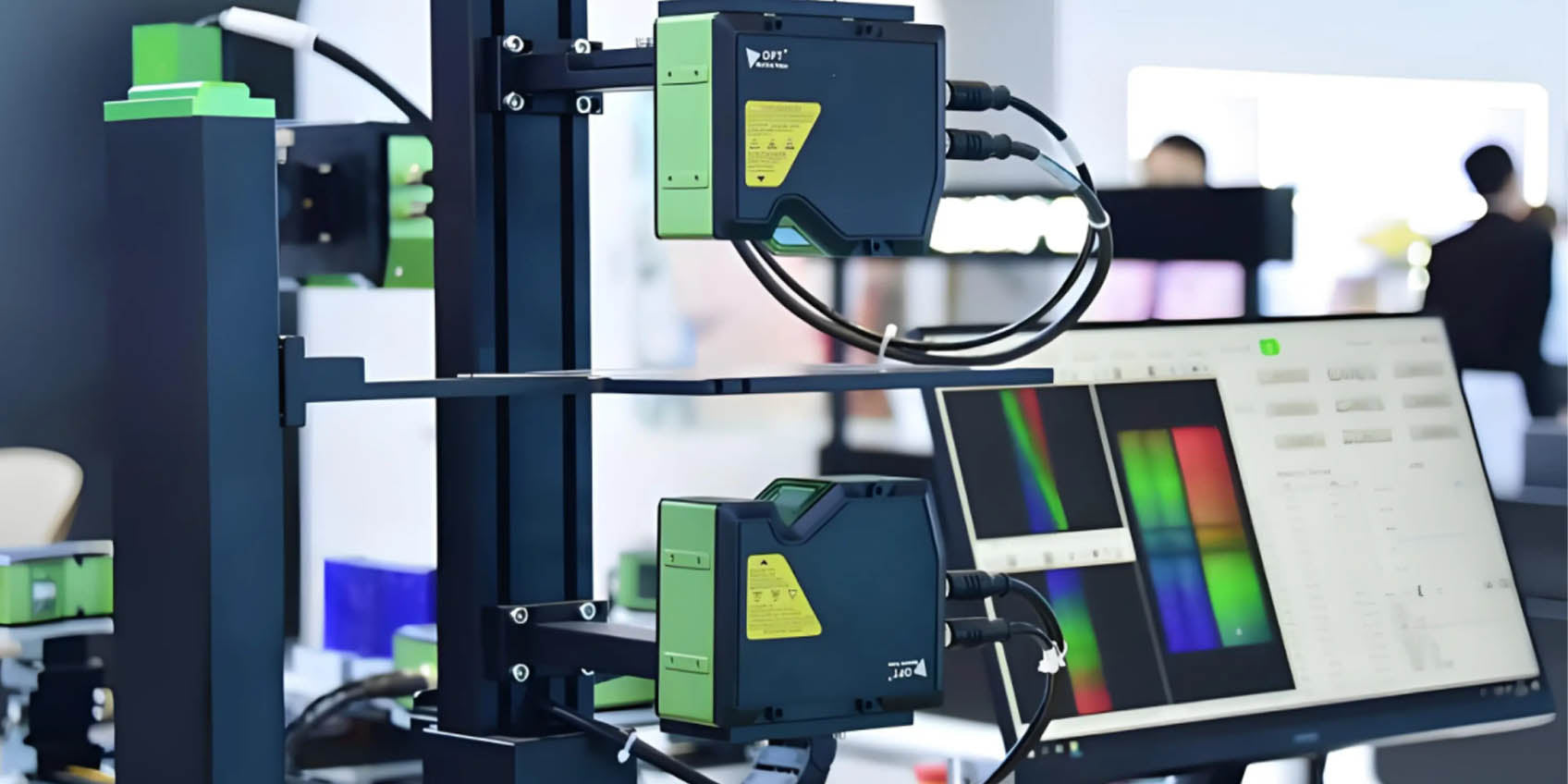

Enhancing 3D Vision Inspection with TOF Technology in Manufacturing

3D Vision Inspection is rapidly becoming an essential part of smart manufacturing, providing highly accurate and efficient quality control in various industries. Traditional 2D vision inspection is often limited by surface-level data, environmental conditions such as lighting, and the lack of depth information. These limitations can result in errors, especially when detecting surface defects, performing precise measurements, or aligning components. TOF (Time of Flight) technology, a cutting-edge 3D perception tool, overcomes these challenges by offering detailed depth information, enabling more precise and reliable inspections.

What is 3D Vision Inspection?

3D vision inspection is a method that uses advanced imaging technologies to capture three-dimensional data about objects, combining it with standard 2D image data for a more comprehensive analysis. It enables more precise measurements, defect detection, and alignment, particularly for complex objects or assemblies. Unlike traditional 2D inspection systems, 3D vision allows machines to "see" depth, shapes, contours, and other essential spatial details. It is ideal for high-precision assembly lines, surface defect analysis, and complex manufacturing environments where exact measurements are critical.

How TOF Technology Enhances 3D Vision Inspection Precision

One of the main benefits of TOF technology lies in its ability to provide high-precision depth measurement by calculating the time it takes for a light pulse to travel from the sensor, bounce off an object, and return. This allows TOF sensors to generate detailed 3D depth data, overcoming the limitations of traditional 2D inspection systems that can only capture flat surface data. As a result, TOF sensors are excellent at detecting fine surface defects, such as scratches, warping, bumps, or even material inconsistencies.

Additionally, TOF technology offers better adaptability to different lighting environments. Unlike traditional 2D vision systems, which can be affected by ambient light, glare, or shadows, TOF sensors are designed to function reliably in both bright and dimly lit conditions. This is crucial in industrial settings where lighting conditions are often inconsistent or challenging. Moreover, TOF sensors, when integrated with AI algorithms, can automatically analyze complex objects, assist in sorting, target recognition, and improve overall assembly accuracy in real-time.

TOF Technology Applications in Electronics Manufacturing

Electronics manufacturing relies heavily on precise inspection to ensure the reliability of components such as printed circuit boards (PCBs), which are integral to most electronic devices. Soldering quality inspection is one such critical task where traditional 2D vision systems fall short due to issues like reflection, occlusion, or inconsistent lighting conditions. TOF sensors overcome these limitations by providing accurate 3D measurements of solder joints, detecting issues like cold solder joints, false soldering, or incorrect solder heights. This ensures that every solder joint is up to standard, preventing faults such as circuit shorts or open circuits.

In chip packaging, TOF technology can measure the thickness of components with high precision, ensuring that the packaging process meets strict standards. Combined with AI-based vision algorithms, TOF sensors can conduct real-time inspections on high-speed automated production lines, immediately identifying and rectifying anomalies. This reduces defect accumulation, improving product yield and reliability.

TOF Technology Applications in Automotive Manufacturing

The automotive industry is another key beneficiary of TOF technology. For automotive manufacturers, precise measurements are essential for ensuring that each component meets the required standards for safety and performance. TOF sensors enable non-contact, high-precision measurements of automotive components, ensuring that dimensions are accurate and parts fit together perfectly. This is especially important in complex processes such as body welding, door installation, and glass bonding, where small deviations can lead to defects or safety hazards.

In automated painting, TOF sensors help measure the coating thickness on car surfaces, ensuring that the application is even and consistent. The 3D vision system can detect issues such as uneven coating, over-thin layers, or defects in the paint, ensuring that the vehicle’s exterior quality meets industry standards.

TOF Technology Applications in Food Packaging Inspection

In the food packaging industry, the integrity of the packaging seals is crucial for maintaining the shelf life and safety of products. Traditional inspection methods, relying on manual checks or 2D vision systems, cannot comprehensively detect problems such as leakage, damage, or deformation.

However, TOF technology can perform precise 3D scans of food packaging, ensuring that even minor seal issues are detected. This non-contact inspection method, when combined with AI algorithms, can automatically detect and remove defective products in real-time during the production process. This ensures that only packaging that meets quality standards reaches the market.

Driving Smart Manufacturing with TOF Technology

With the rise of Industry 4.0, the manufacturing industry is evolving towards more intelligent, automated, and high-precision production systems. TOF technology plays a pivotal role in this transformation by enhancing the capabilities of 3D vision inspection. In the future, as TOF sensors improve in resolution and AI-powered analysis becomes more sophisticated, TOF technology will continue to expand its applications across a range of industries, including robot vision, logistics sorting, smart warehousing, and more. This will help optimize the manufacturing process, reduce defects, and drive greater efficiency and accuracy.

Conclusion

TOF technology is revolutionizing the way industries approach quality control and 3D vision inspection. With its ability to provide high-precision depth measurements, fast data processing, and adaptability to diverse environmental conditions, TOF sensors are essential in fields such as electronics manufacturing, automotive production, and food packaging. As smart manufacturing continues to evolve, TOF technology will play an increasingly significant role, improving production quality, efficiency, and overall competitiveness in the global market. As we move forward, TOF technology will be at the heart of industrial automation, shaping the future of manufacturing.

IHaw Structured Light Camera P050 0.50M

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.

-

Posted in

P050