How TOF Technology Boosts 3D Vision Inspection in Smart Manufacturing

In the era of Industry 4.0, 3D vision inspection has become indispensable for ensuring the precision and quality of products in industrial manufacturing. Unlike traditional 2D vision inspection, which captures only flat, two-dimensional data, 3D vision inspection provides essential depth information, making it suitable for detecting surface defects, measuring dimensions, and ensuring precise component alignment. Traditional 2D vision systems often struggle with lighting conditions, angle variations, and material factors, making it difficult to achieve high-quality results. However, TOF (Time of Flight) technology, by measuring the time it takes for light pulses to travel to an object and return, offers high-precision 3D depth information, enabling superior inspection capabilities that traditional methods cannot match.

What is 3D Vision Inspection?

3D vision inspection involves the use of advanced 3D imaging technology to capture both the spatial and depth information of an object, providing a more comprehensive view than 2D systems. This method combines 3D depth data with 2D image data, offering increased accuracy for complex tasks such as defect detection, dimension measurement, and position alignment. 3D vision inspection is widely used in robot navigation, automated assembly, and product quality control in industries ranging from electronics to automotive and food packaging.

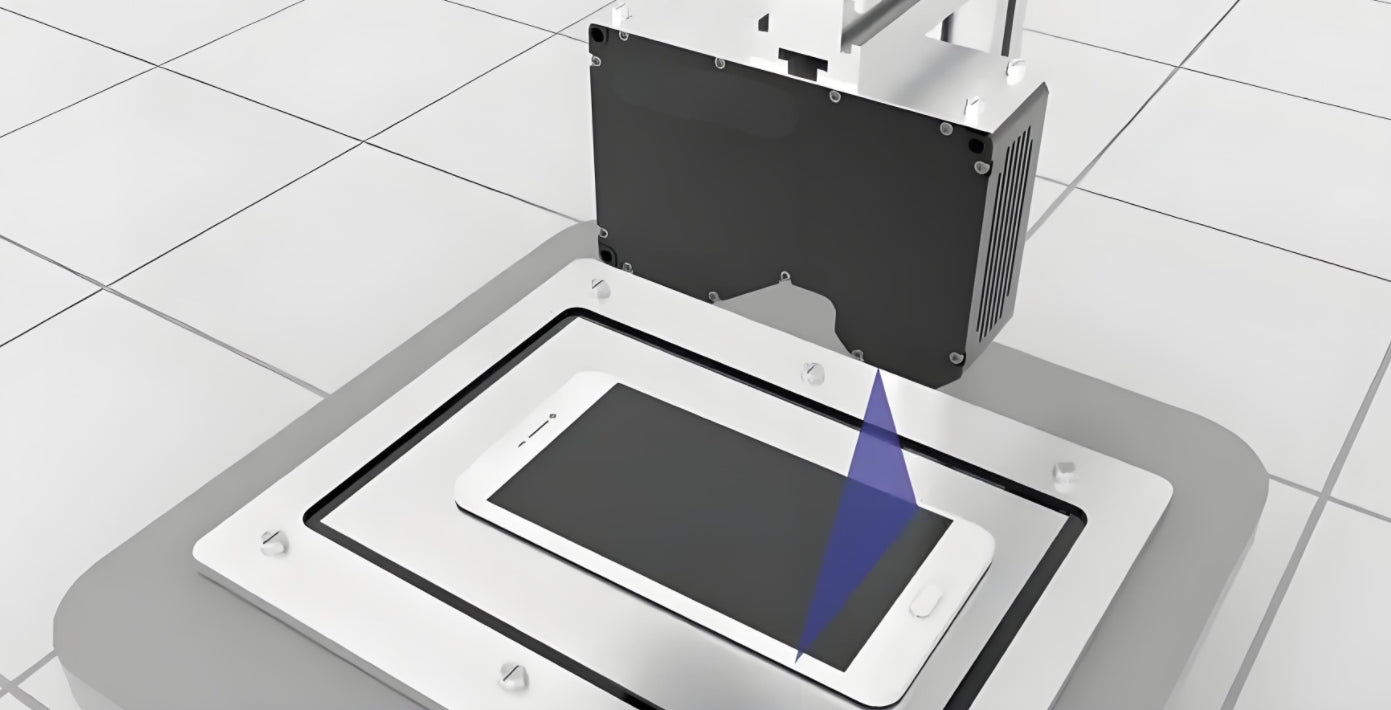

How TOF Technology Improves 3D Vision Inspection

The primary advantage of TOF technology lies in its ability to provide high-precision depth data in real time. While 2D vision systems can capture only the flat surface of objects, TOF sensors use light pulses to measure the time taken for the light to reflect back from an object, which directly translates to depth information. This enables TOF sensors to create accurate 3D models of an object’s surface, which is vital for identifying fine defects such as scratches, dents, and misalignments.

TOF sensors offer additional advantages over traditional vision systems, such as better adaptability to various lighting conditions. Whether in bright, low, or uneven light environments, TOF technology remains stable, delivering precise data without being affected by external lighting variables. This is particularly beneficial for applications in complex manufacturing environments where lighting conditions can fluctuate throughout the production process.

Moreover, TOF sensors can capture data at incredibly high speeds, enabling real-time feedback for automated systems. Combined with AI algorithms, TOF technology enhances the ability of industrial automation systems to make intelligent decisions, such as target recognition, sorting, and defect detection, resulting in improved product quality and increased operational efficiency.

TOF Technology Applications in Electronics Manufacturing

In electronics manufacturing, where precision is paramount, TOF sensors have revolutionized the quality control process. A key application is in PCB soldering inspection, where traditional 2D vision systems may struggle due to reflections, occlusions, or difficulty in detecting the uniformity of solder joint height. With TOF technology, manufacturers can accurately measure solder joint height and shape, ensuring that every joint meets the required standard and preventing issues like cold solder joints, false soldering, or improper soldering height that could lead to defects in the circuit.

During chip packaging and inspection, TOF sensors can also measure the thickness and alignment of components, ensuring high precision in the packaging process. This real-time inspection prevents faulty products from entering the market, improving the yield and reliability of electronic products in mass production.

TOF Technology Applications in Automotive Manufacturing

The automotive industry requires strict precision in the measurement and assembly of vehicle parts to maintain safety and performance standards. TOF sensors provide non-contact, high-precision measurement capabilities, enabling manufacturers to ensure that every part is produced and assembled according to strict specifications. From body welding and door installation to glass bonding, TOF sensors can detect height differences at joints, identify welding defects, and ensure that parts are installed with optimal precision.

In automated painting and surface inspection, TOF sensors combined with 3D vision technology allow for accurate measurements of the coating thickness of vehicle surfaces. This ensures that the exterior finish of vehicles meets the desired standards, without uneven coating or defects, maintaining both the aesthetic and functional integrity of the vehicles.

TOF Technology Applications in Food Packaging Inspection

The integrity of food packaging plays a crucial role in ensuring the safety, shelf life, and quality of products. Traditional inspection methods often rely on manual sampling or 2D vision systems, which are limited in detecting issues like deformation, sealing defects, or leaks in packaging. TOF sensors can precisely measure the shape, alignment, and integrity of food packaging in 3D, detecting even the smallest defects that could compromise food safety.

In high-speed production environments, TOF technology offers a significant advantage in online inspection of packaging processes. By combining TOF sensors with AI-powered algorithms, manufacturers can automatically detect defective packages and remove them from the production line in real-time, ensuring that only products meeting strict quality standards reach the market.

TOF Technology Driving Smart Manufacturing

As manufacturing continues to embrace Industry 4.0, the demand for more precise, efficient, and automated production systems has never been higher. TOF technology, with its ability to provide real-time, high-precision depth data, is helping industries transition toward smart manufacturing by enabling smarter and more automated quality control systems.

Looking ahead, as TOF sensors evolve in terms of resolution, computational power, and integration with AI deep learning systems, the scope of their applications will continue to expand. The technology will be increasingly used in areas such as smart warehousing, robot vision, logistics sorting, and automated inspections, further promoting the intelligent automation of manufacturing processes and increasing the competitiveness of industries worldwide.

Conclusion

In conclusion, TOF technology is transforming the landscape of 3D vision inspection, making it a vital tool in smart manufacturing. With its ability to provide high-precision measurements, fast data processing, and adaptability to various lighting conditions, TOF sensors are enhancing industrial applications in fields such as electronics manufacturing, automotive production, and food packaging. As the industry moves toward increased automation and precision, TOF technology will continue to play a central role in driving the future of industrial automation, ensuring higher product quality, greater efficiency, and a competitive edge for manufacturers worldwide.

IHawk Structured Light Camera P100E 8M

After-sales Service: Our professional technical support team specializes in TOF camera technology and is always ready to assist you. If you encounter any issues during the usage of your product after purchase or have any questions about TOF technology, feel free to contact us at any time. We are committed to providing high-quality after-sales service to ensure a smooth and worry-free user experience, allowing you to feel confident and satisfied both with your purchase and during product use.

-

Posted in

P100E